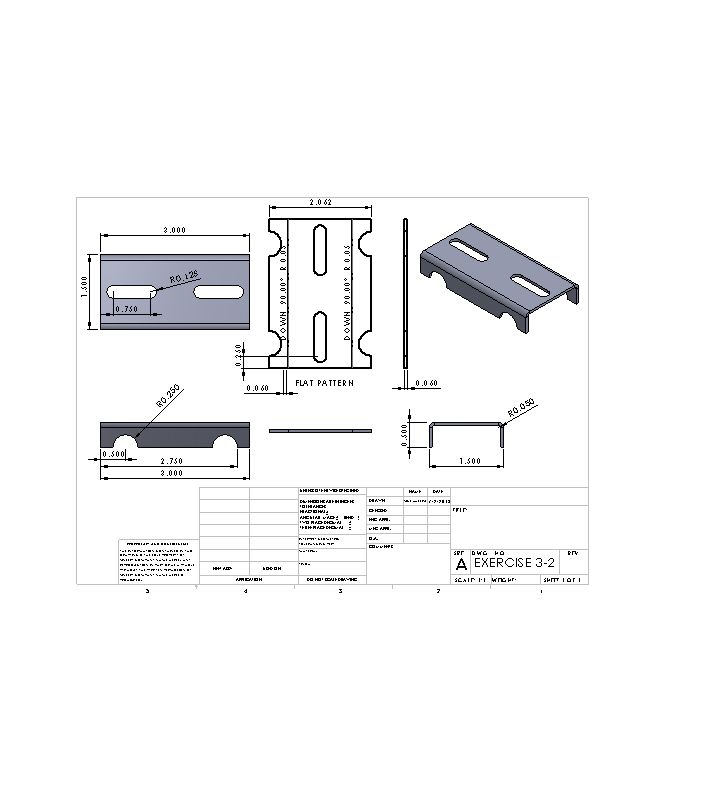

sheet metal drawing example

SMACNA CAD STANDARD SHEET METAL AND AIR CONDITIONING CONTRACTORS NATIONAL ASSOCIATION INC. Similar to other metal forming processes bending changes the shape of the work piece while the volume of material will remain the same.

Sheet Metal Drawing Sheet Metal Drawing Sheet Metal Sheet Metal Work

However sheet metal parts also require specific data to be shown on the drawing to.

. For example there are numerous elements that can be added to steel in the liquid state during metalworking and that determine the material properties of the sheet metal produced. 12 Full PDFs related to this paper. SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly.

Press working operationsSheet Metal Operations. Metal sheet Blank holder ring on cushion Compressible cushion Sheet metal stampingdrawing car industry 90million cars and commercial vehicles produced worldwide in 2014. It leaves a lean edge on the piece of metal is sheared or cut.

3D CAD files are converted into machine code which controls a machine to precisely cut and form the sheets into the final part. Step 2 Create a dummy part in this new template for example a rectangular block and save. Could the part be designed following sheet metal rules rather than being converted from a solid.

For example 8-gauge sheet metal is thicker than 16-gauge sheet. 3 Deep Drawing Operation. This also means that tolerances in the title block of a drawing may be unnecessarily restrictive for certain dimensions and angles while very appropriate for others.

Sheet metal workers need good handeye coordination and motor control to make precise cuts and bends in metal pieces. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapesCountless everyday objects are fabricated from sheet metal. Sheet metal is metal formed by an industrial process into thin flat pieces.

Sheet metal fabrication is a valuable prototyping and production method for making robust functional parts like panels brackets and enclosures. Edit the sheet format Edit Sheet format and add a new note where you want the weight to display Insert Annotations Note. Step 3 Create a new drawing of this dummy part insert at least one view of the part.

Thicknesses can vary significantly. Bending is one of the most common sheet metal fabrication operations. Sheet metal is any metal that has a thickness in between 056 millimetres.

Super-plastic forming cheap tooling net thinning slow. Gauges are independent of common measurement systems and are used to determine sheet metal thickness in inches or millimeters. Mechanical engineers will specify the approved hanger methods in the specifications if.

The force must exceed the materials yield strength to achieve a plastic deformation. Critical Dimensions Sheet Metal Forming Outside dimension should be used unless the inside dimension is critical. Sheet metal workers must calculate the proper sizes and angles of fabricated sheet metal to ensure the alignment and fit of ductwork.

However in some circumstances when the design demands certain types of geometries the user has the option to use non-sheet metal feature tools and then use the Insert Bends or Convert to Sheet Metal features. Sheet metal workers use saws lasers shears and presses. Sheet Metal Box 51 REQUIRED VIEWS Formed sheet metal parts must be fully defined as a finished good in the completed folded state per section.

Full PDF Package Download Full PDF Package. A large variety of deburring chamfering bending and other secondary processing operations may be employed to produce sheet metal product with edges of the desired geometry and quality. Deviations from the drawing.

Various types of materials are available on earth. Millimetres Mils Gauge. Various measuring systems are used today and the measured values vary depending on the type of metal used.

Its remarkable feature is that the thickness of the same part is the same. Each material has its advantages limitations and applications. Foils sheets and plates are pretty much the same with the only difference being in thickness.

The more we know about fabrication costs the more. Sheet metal bending is the plastic deformation of the work over an axis creating a change in the parts geometry. Lead times can be shortened once material grades are taken into consideration.

Stamping Auto body panels 3 to 5 dies each. Sheet metal material selection is an iterative process. Here is a simple example to illustrate the point.

Punching is a forming process that uses a punch press to force a tool called a punch through the workpiece to create a hole via shearingPunching is applicable to a wide variety of materials that come in sheet form including sheet metal paper vulcanized fibre and some forms of plastic sheet. It is a Sheet Metal forming process in which a sheet metal blank is radially. For example the process of sheet metal expanding involves cutting multiple slits in the metal then stretching the sheet open like an accordion.

Chapter 3 Sheet Metal Duct Hangers Air conditioning ducts and pipes need to be supported according to code approved methods. In addition to silicon nickel and chromium these elements also include titanium copper niobium and molybdenum. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching cutting stamping and bending.

Where I want bends there has to be accommodations in the body for the bends as defined by the sheet metal rules. This is done through the application of force on a workpiece. You need to confirm that the hangers you intend to use are approved in the local area where the building is located.

Cutting factors have much to do with sheet metal edges for example a larger burnish zone would be indicative of a better edge surface quality. The operations performed on the sheets to get the required shape is called sheet metal operations. Sheet metal fabrication is a comprehensive cold-working fabrication process for sheet metal usually less than 6mm including shearing blanking bending welding riveting die forming and surface treatment etc.

As for the compound curves where the flat surface of the faces curve to meet the 6 hole breaks the sheet metal rules. The punch often passes through the work into a dieA scrap slug from the hole is. Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm.

Sheet metal fabricators also have these same choices. Bending of sheet metal is a common and vital process in manufacturing industry. A short summary of this paper.

Sheet Metal Forming 2810. Drawing embossing flanging and hemming. In this operation a sheet metal workpiece is placed or kept between two dies from one end.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape. Sheet metal is one of the shapes and forms metal can be bought in. Below drawn figure is an example of Edge Bending.

The sheet metal is clamped on its periphery to prevent material drawing into the cavity and is afterward stretched over a hemispherical punch which has to replicate the dies utilized in the real deep-drawing process in terms of both material and surface finishing. There are other measurement units used to categorise metals by thickness though. After the material selection it should be validated and tested according to the product design requirements.

It is a cut in a straight line across a strip sheet or bar.

Using Solidworks Sheet Metal Functionality Create A B Size Drawing Sheet Metal Drawing Technical Drawing Mechanical Engineering Design

China Acculine Sheet Metal Deep Drawing Quality Control Inspection Report Example Cs080003 By Acculine Precision Manufacturin Deep Drawing Sheet Metal Drawings

Construction Set For Sheet Metal Scale Model Making Sheet Metal Drawing Solidworks Tutorial Sheet Metal

Solidworks Tutorial Sheet Metal Drawings Youtube Sheet Metal Drawing Solidworks Tutorial Solidworks

Advanced Sheet Metal Exercise In Solidworks Youtube Solidworks Tutorial Solidworks Sheet Metal Drawing

Pin By Fgnkrsc On My Drawings Sheet Metal Drawing Drawing Sheet Mechanical Design

Esercizio 54 Sheet Metal Drawing Mechanical Design Technical Drawing

Solidworks 2013 Sheet Metal Metal Furniture Design Metal Sheet Design Sheet Metal Fabrication

Chassis Drawing Sheet Sheet Metal Drawing Sheet Metal Drawing Sheet

Pin On My Fun With Blender 3d Software

Pin By Petr Lost On Aut C D Sheet Metal Drawing Drawing Book Pdf Autocad Isometric Drawing

I Want Sheet Metal Part Drawings To Practice Iam Not Able To Get From Google Can Anyone Pls Help Me Grabcad Que Sheet Metal Drawing Sheet Metal Drawing Sheet

Sheet Metal Drawing Sheet Sheet Metal Drawing Drawing Sheet Sheet Metal

Angle Bracket Sheet Metal Drawing Sheet Metal Technical Drawing

This Drawing May Differ From The Actual Product Drawing An Educational Example For Students Learnin Mechanical Engineering Design Solidworks Tutorial Autocad